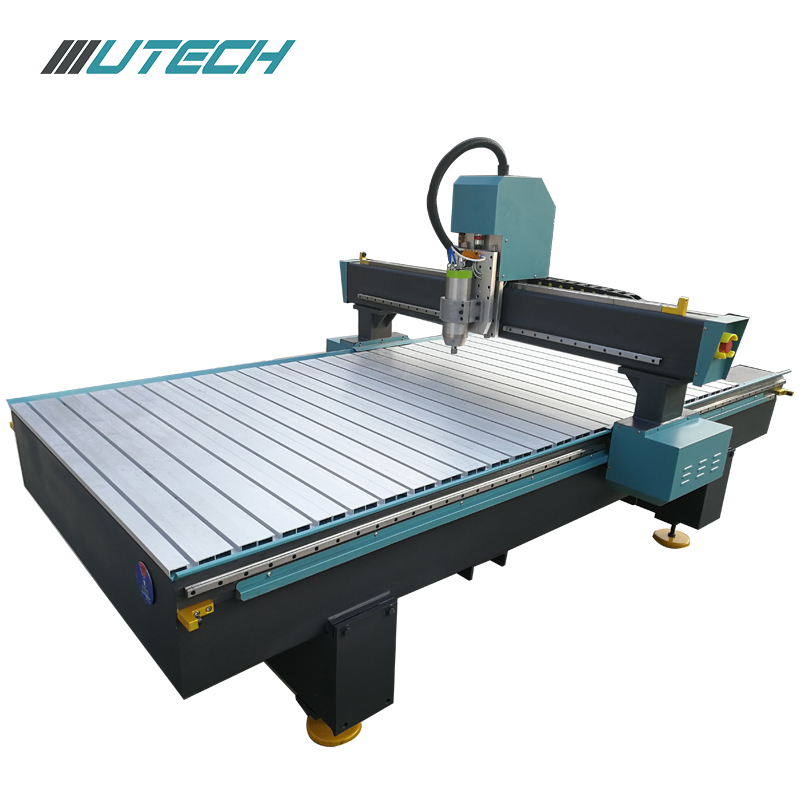

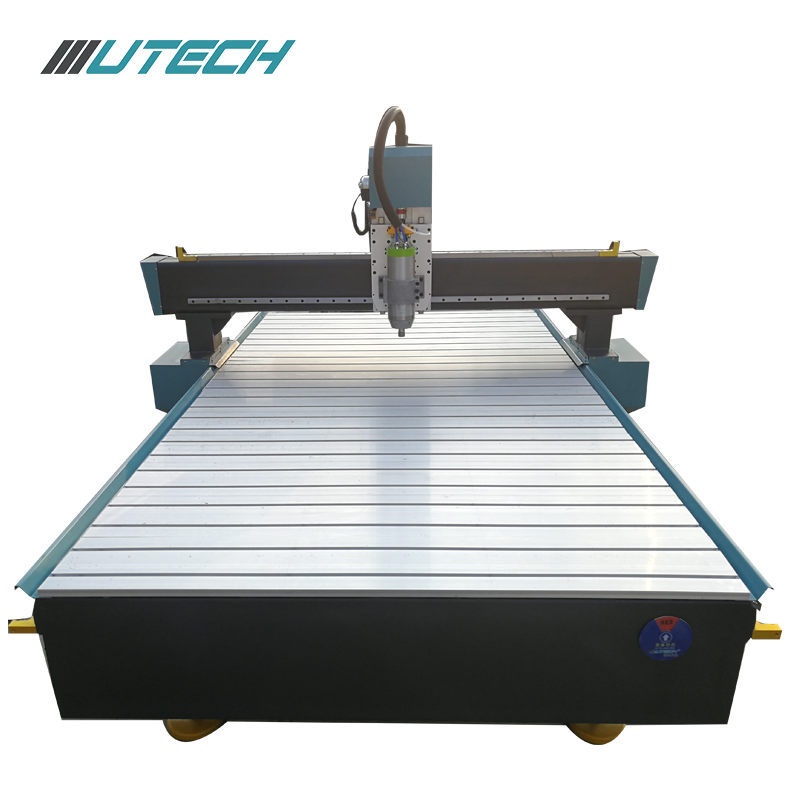

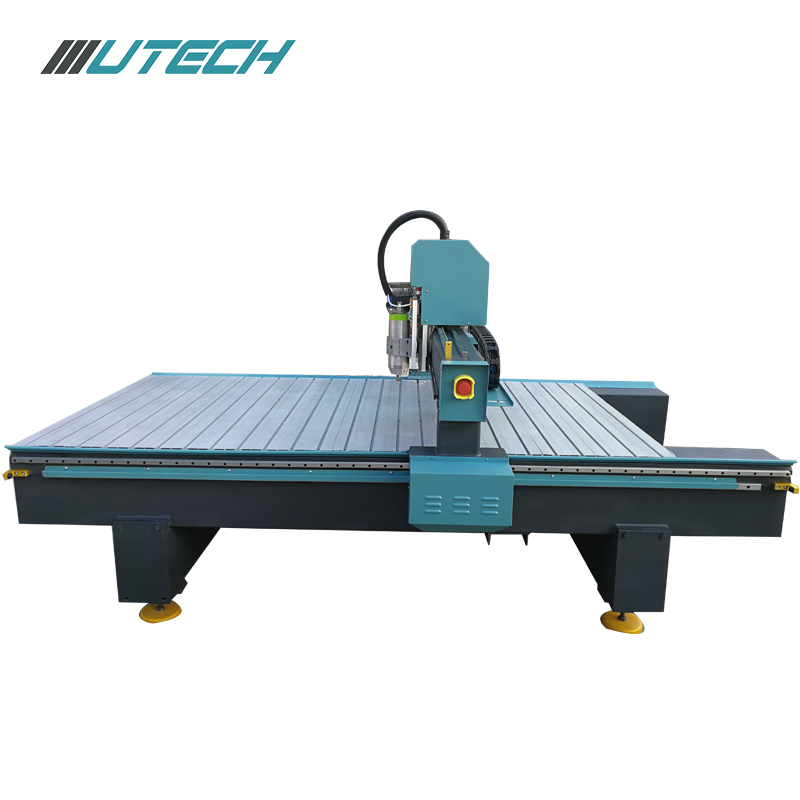

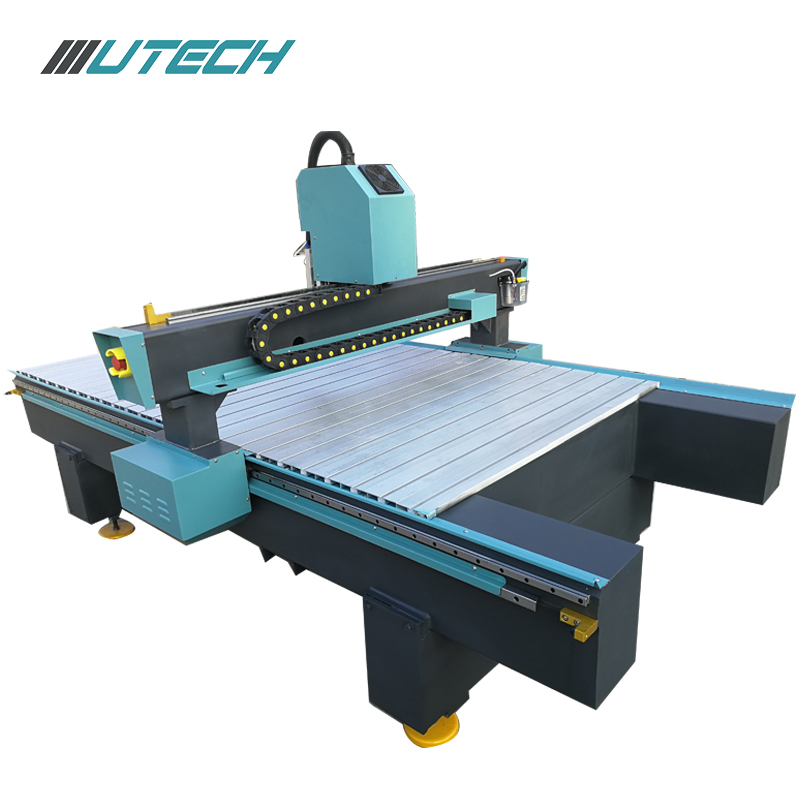

cnc router engraver milling machine

Basic Info

Model No.: Sesame

Brand: Utech

Resolution: 0.01mm

Machine Weight: 1000kg

Spindle Speed: 0-24000rpm

Table Structure: T-slot Table

Command Code: HPGL G-code

Travel Speed: 0-25000mm/min

Working Speed: 0-18000mm/min

Driving Mode: Patent Stepper Reducer Structure

Spindle Power: Woodworking Cnc Router

Working Area: 1220*2440*150mm

Additional Info

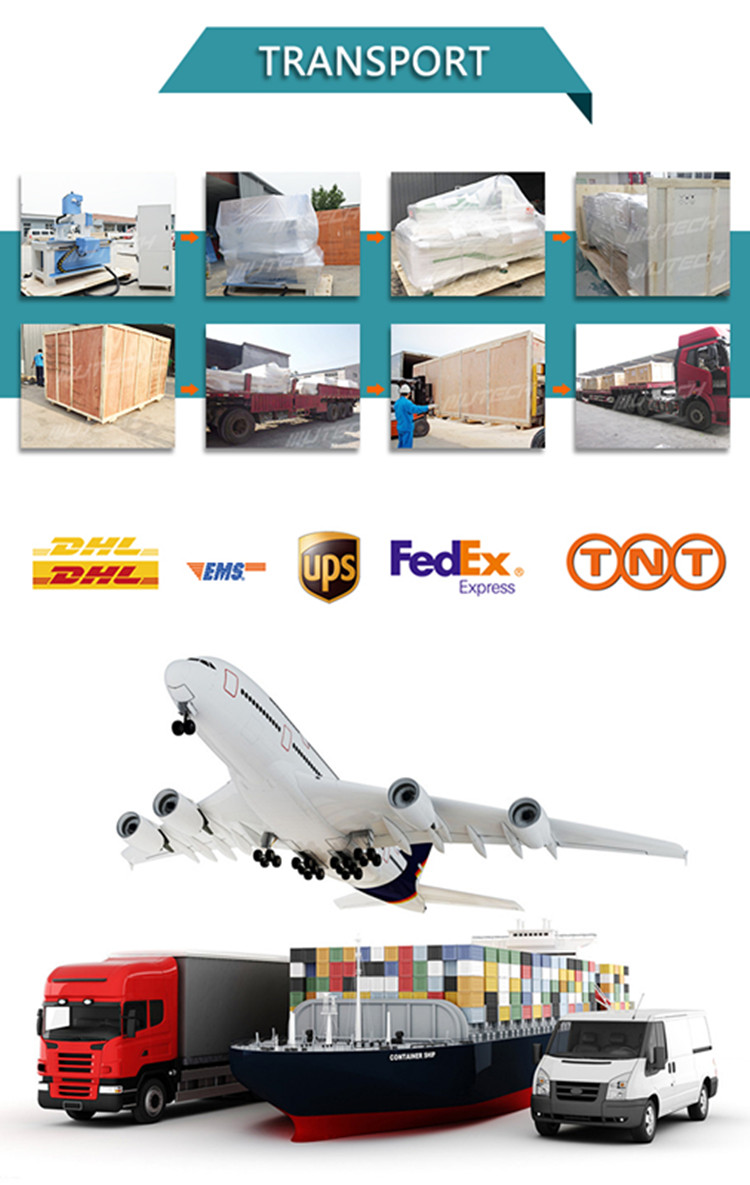

Packaging: Wooden case packing

Productivity: 1000 sets

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 1000 sets per month

Certificate: ISO 9001

HS Code: 8465990000

Port: Qingdao,Shanghai,Shenzhen

Payment Type: L/C,T/T,D/P,Paypal,Money Gram,Western Union

Incoterm: FOB,CFR,CIF,FCA,CPT

Product Description

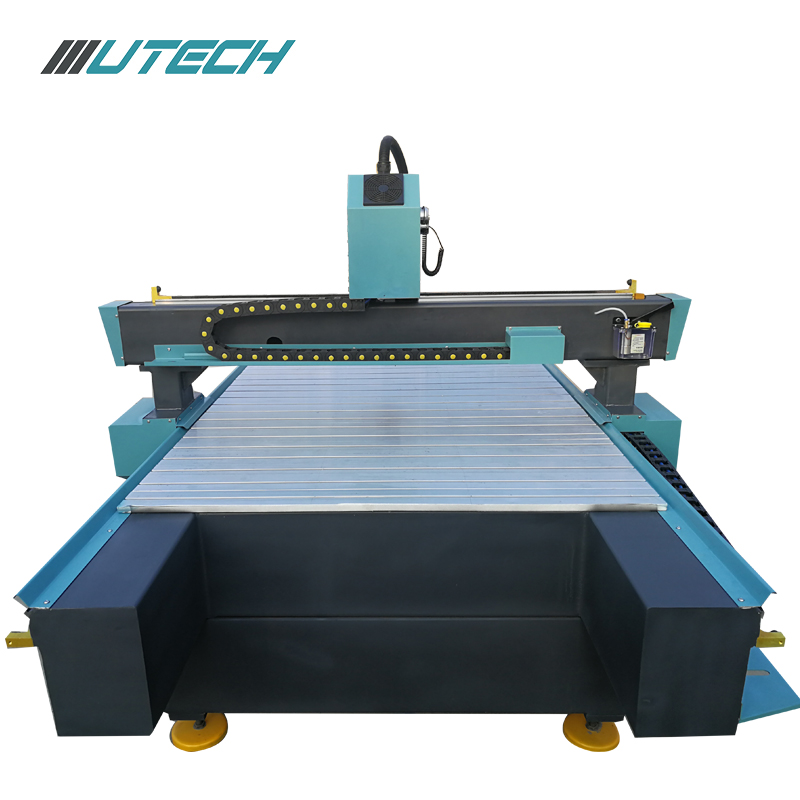

Cnc Router engraver milling machine

Sesame with high power spindle with good rigidity not only demonstrates superior performance in woodworking application, is also propitious to engrave and cut on copper, aluminum, iron and other metals. With imported rack and gear transport system, largely improve the speed of the machine.

| Model | Sesame |

| Working Area | 1300*2500*150mm |

| 1300*2500*200mm | 1120*2440*150mm |

| Table structure | T-slot table |

| Transmission Device | X, Y axis: Precision helical tooth gear transmission |

| Z axis: Precision tBI ball screw | |

| Travel speed | 0-25000mm/min |

| Working speed | 0-18000mm/min |

| Driving mode | Patent stepper reducer structure |

| Spindle power | 3.2KW water cooled spindle motor |

| Spindle speed | 0-24000rpm |

| Diameter of cutter | φ3.175-φ12.7mm |

| Command code | HPGL G-code |

| Working voltage | AC220V/Hz |

| Device interface | Standard PCI/USB interface optional |

| Resolution | 0.01mm |

| Machine size(W*D*H) | 1935*3015*1500mm |

| Warranty | 12 months |

| 12 months | 1000kg |

Warm tips: all parts of the machine can be upgraded or changed. Please tell us your material and size. We will customize the most suitable machine for you.

| CONFIGURATION |

| 3.2kw water/3.5kw air cooled spindle |

| Nc-studio controller |

| XY axis by Patent type reducer structure 1:4+450B transmission structure, Z axis by Taiwan TBI ball screw(Disc coupling direct connection.); XYX axis by JMC 860 driver. |

| Xinfutai inverter |

| Double stop protection device |

| Portable control box, place the position saving device to take up space. |

| The equipment is equipped with a professional forklift station to facilitate loading and unloading equipment. |

| Humanized mechanical structure design, optimized product packaging method to save transportation cost. |

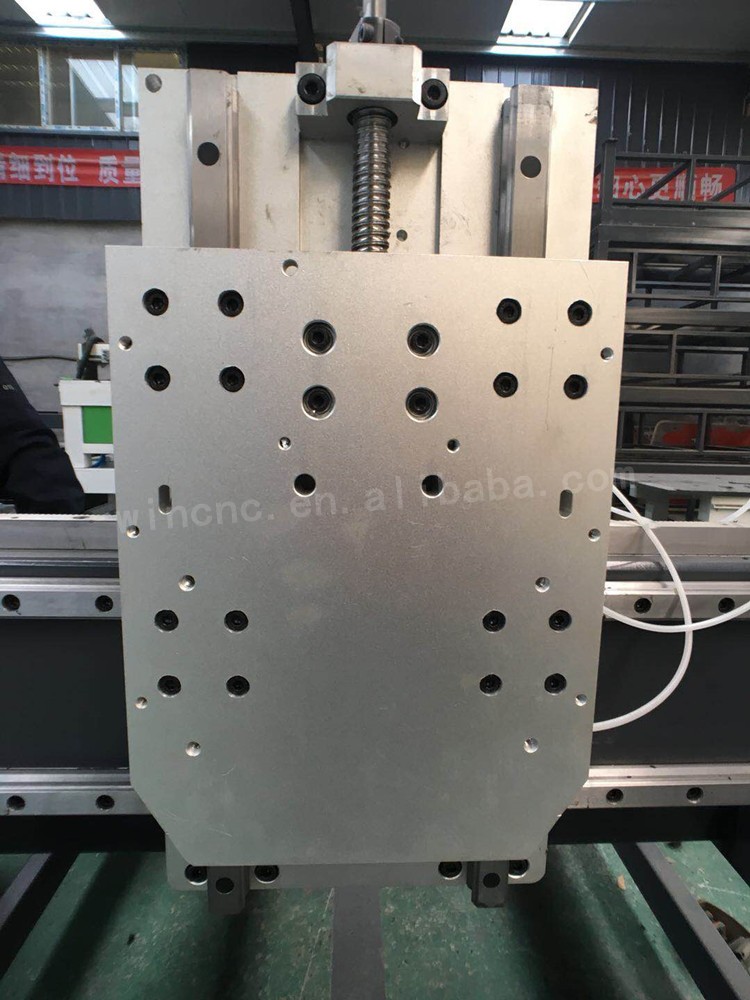

| Taiwan PMT 20 guide rail+20mm flange slider |

| Y-axis double protection anti-dust optimization design,better protection of linear guide service life. |

| Nc center precision machining T6 material precision machine head accessories set. |

| Square pipe welding bed structure. |

| T-slot table |

| Electronic inductance limit switch. |

| Tool sensor |

| Tool box(parameter list/controller install software/drawing software/etc),cutters, etc. |

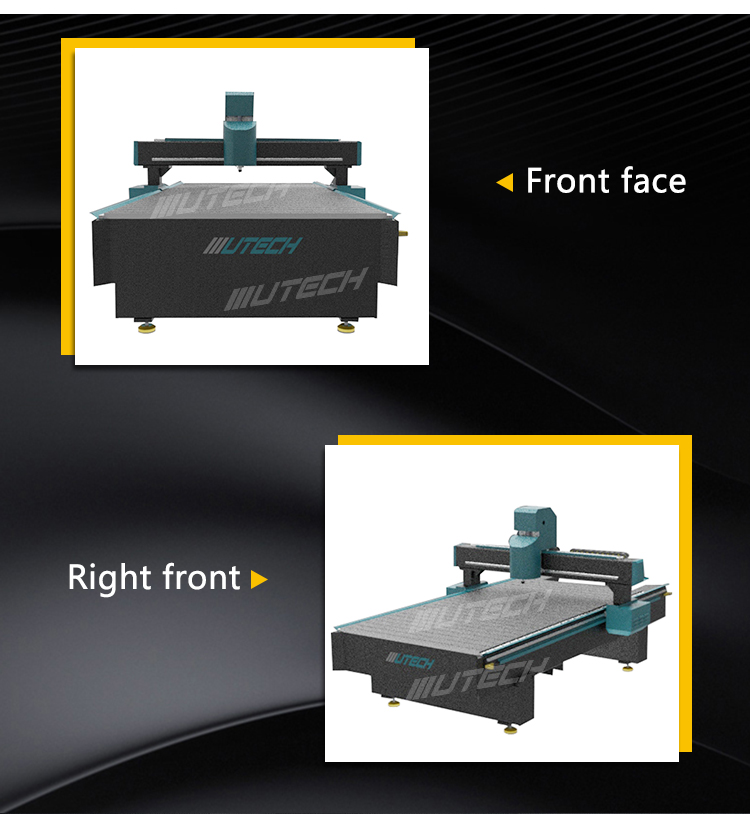

Detailed Images

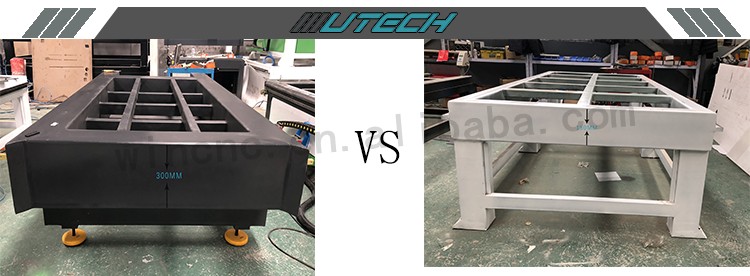

1/ Machine bed with 200*300mm square tube welded together, compared to ordinary machines, we use the square tube model can better reflect the stability of the equipment.

2/ Bed welding process increases the reserved forklift, highlights two major advantages: First, increase the strength of the bed itself; Second, it`s more convenient for customers to disuse the equipment.

3/ we adopt separated type lathe bed structure. With the purpose of: After ensuring that the customer receives the equipment, there`s no need to make a complete disassembly and will not affect the operation of the equipment. In this circumstance, we optimized the design structure, then, the final packaging size of the product was saved by 5m³.Thus saving transportation costs.

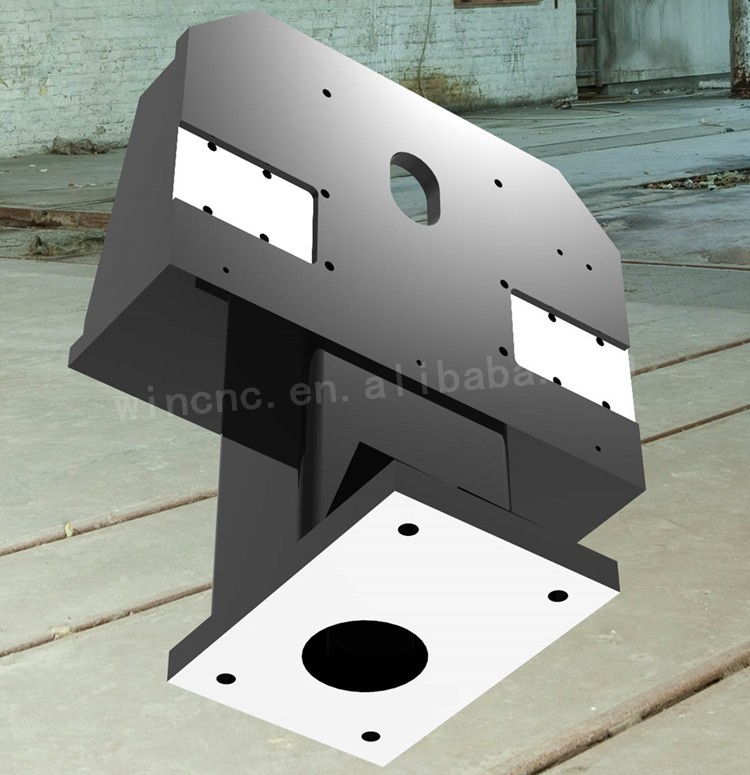

4/ Transmission column, we adopt high - precision machining process, ensure the accuracy of accessories. Like insert cavity position, assembly surface.

5/ First, For the choice of hand piece, we choose T6061/6063 aviation aluminum alloy as the base material. Through the precision processing of CNC Processing Center, we finished our finished parts. Second, the high requirement assembly process ensures the precision of the product.

6/ Choose heavy duty linear guide rail with high assembly flange sliding block.

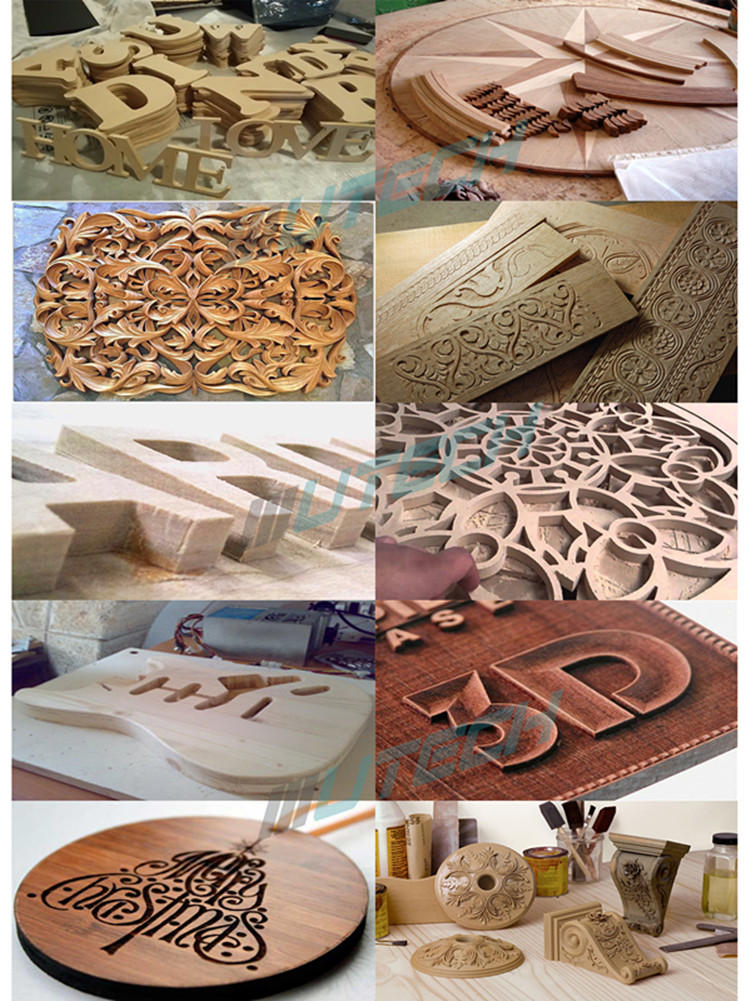

Applications

Advertising industry | Acrylic cutting, density board cutting, snowflake cutting, double color board carving, various advertising boards. |

Furniture industry | Cabinet doors, wooden doors, solid wood, mahogany furniture, antique furniture, all kinds of composite sheet cutting carving. |

Plate processing industry | Insulation board, plastic work piece, PCB board, anti-double board, epoxy resin, ABS, PP, PE and other carbon mixtures. |

Crafts industry | Artificial marble, PVC, wood, plexiglass, copper aluminum and so on. |

Decoration industry | The screen, wave plate, wood, artificial marble, organic board, decorative board, double color board and other materials on various exquisite patterns and text carving. |

- The bed is welded with thick wall steel tube,Integral thickening square tube, solid and not deformed. After high temperature tempering treatment to ensure the best strength and rigidity.

- The machine head is made of T6061/6030 aluminum parts by professional CNC machining center. After oxidation surface and low temperature annealing treatment, the machine head is lighter and more durable.

- Use 3mm metal sheet for the dust cover,more than ten working procedure, Professional beauty and correction.

- Use Germany ASK 25mm square rails.The Y-axis adopts double-row four-column guide rail, with strong bearing force, fast speed, smooth operation, high precision and high life span.

- Rack adopts German imported high-precision helical rack, which is complementary with the servo motor and professional deceleration device, which runs smoothly, high speed, high precision and low noise..

- Use Simple servo motor, the machine torque is big, processing speed is quick, the highest speed can reach 40m/min.With reducer transmission, the machine is more stable, high efficiency, high precision and low noise.

Standard accesstories:

- user's manual for use and maintenance

- bit collects

- spanner for changing the bits

- flash disk for installation of control system

- data wire

- others

No matter when and where, when I receiveyour message, I will put down any work I have at hand to respond to you and provide service for you.

Product Categories : Cnc Router Series > Woodworking Cnc Router